Locomotive practice pieces

Five-hundred apprentices are being trained at the new Apprentice Workshop of Deutsche Bahn (DB)

The new three-story building of the Apprentice Workshop in Johannisthal is flooded with light and accommodates more than 500 trainees. The space on the premises of the S-Bahn railyard in Schöneweide had become too small and remodelling was not an option. In September 2023, the first apprentices already moved into a newly renovated, rented building that’s just one kilometre away, says Silke Klein-Jente, who has been at the helm of DB Training’s Apprentice Workshop since 2010.

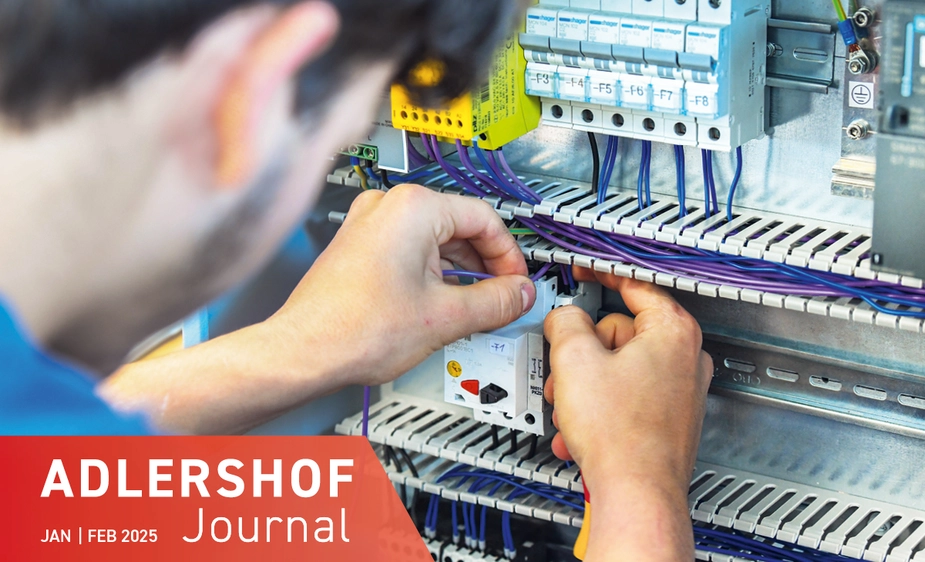

The state-certified technician leads through six large, bright rooms spread across three floors, where apprentices are diligently testing sensors, working on circuit boards, filing, drilling, milling, or soldering at their workbenches. ‘I’m making a module here that can regulate the tones of an electric guitar,’ explains Niklas Gohlke. Asked what guitars had to do with the German national railway company, he says: ‘It’s about gaining an understanding of electronic regulation.’ He’s always been interested in hands-on work, and since he couldn't find a specialised position in his hometown of Cottbus, he applied to Deutsche Bahn and is now in the third year of his apprenticeship to become an electronics technician for device systems. After successfully completing his training in two years, Gohlke plans to stay with the company, in Cottbus, where a new DB maintenance facility is set to be completed by 2026.

‘We've filled all the apprenticeship positions now,’ says Klein-Jente. However, it is becoming increasingly difficult to fill all the spots. Apprentices are trained in areas like mechatronics, industrial mechanics, electronics for devices and systems, or automation technology. This is also done using innovative learning methods, such as using virtual reality headsets. The recruitment of apprentices is handled by various railway companies, including S-Bahn, the DB’s long-distance services, or DB Energy, but external companies like Schindler or DHL can also take advantage of the programme. Throughout their three-and-a-half-year dual apprenticeship, the trainees receive a total of 46 weeks of instruction at the DB training centre. ‘We have about 25 learning facilitators responsible for this, who have already gained several years of work experience in their field and receive additional educational qualifications from us,’ says Klein-Jente. Additional training like programming or operating machinery is also offered. Further, it is important, she says, to have ‘a feeling for young people,’ which is hard to gain solely through professional experience. Here, one might benefit from taking on a role like coaching in a sports club.

‘I enjoy training young people. For me, this is not just a job, but a calling,’ says one of the learning facilitators for the Electronics for Devices and Systems department. The new, modernly equipped building is ‘a milestone and meets all the requirements me and my colleagues have with its large, clearly structured spaces.’ The qualified commercial vehicle mechatronics technician has been preparing apprentices by teaching them the fundamentals of measurement technology for about ten years. Around 10–15 percent of the apprentices are female.

‘I've always been interested in technology,’ says Jane Reich, who is currently practising how to lay cables. She has already done some programming at school and then completed a technical year for women. Afterward, she looked for a career that would combine programming and logical thinking with practical application. Reich, who grew up in Kleinmachnow and currently lives in Berlin, applied to several companies and chose Deutsche Bahn for her apprenticeship in automation technology. ‘I wanted a structured apprenticeship where I know what I’m doing and why I'm doing it.’ This is exactly what DB offers: ‘A clear structure. I already know weeks in advance what I have to do.’

Last week, she worked on soldering, which she was already somewhat familiar with, but she found it a bit easier than her current task—stripping wires and re-wiring them correctly. ‘There’s a lot of skilled craft involved, but it’s also something that’s new and interesting to me.’ She also appreciates the variety, rotating between training on-the-job, the Apprentice Workshop, and vocational school.

In the last room of the tour, the metalworking area with milling and drilling machines, even laypersons with less technical expertise might be able to see the appeal. The tables are full of small and large metal locomotives, reminiscent of one’s childhood and the joy of watching model locomotives and railway carriages driving in circles. ‘We have 28 vices and 12 milling and turning machines,’ says learning facilitator Frank Schumacher. ‘With these, we manually and mechanically lay the foundations for training in the metalworking field.’ The trainees manufacture practice pieces, blocks with defined dimensions, and also projects that take several weeks, such as the locomotives. ‘Some we keep as display pieces to show what our apprentices are capable of making here.’

Dr. Paul Janositz for Adlershof Journal

DB press release on the opening of the Apprentice Workshop in Berlin (in German)